What is a Battery Test System and How Does It Work?

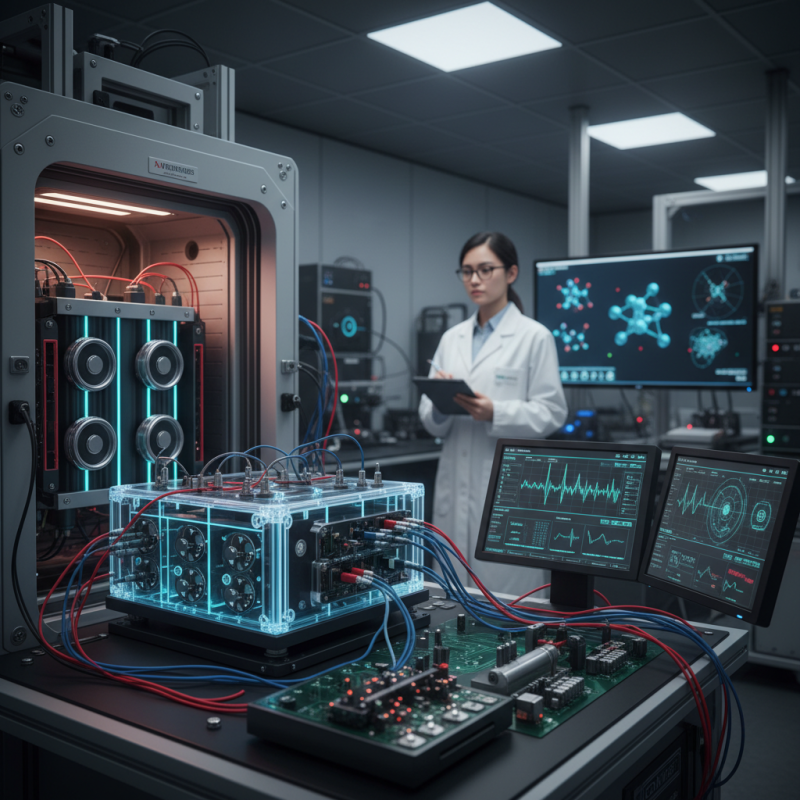

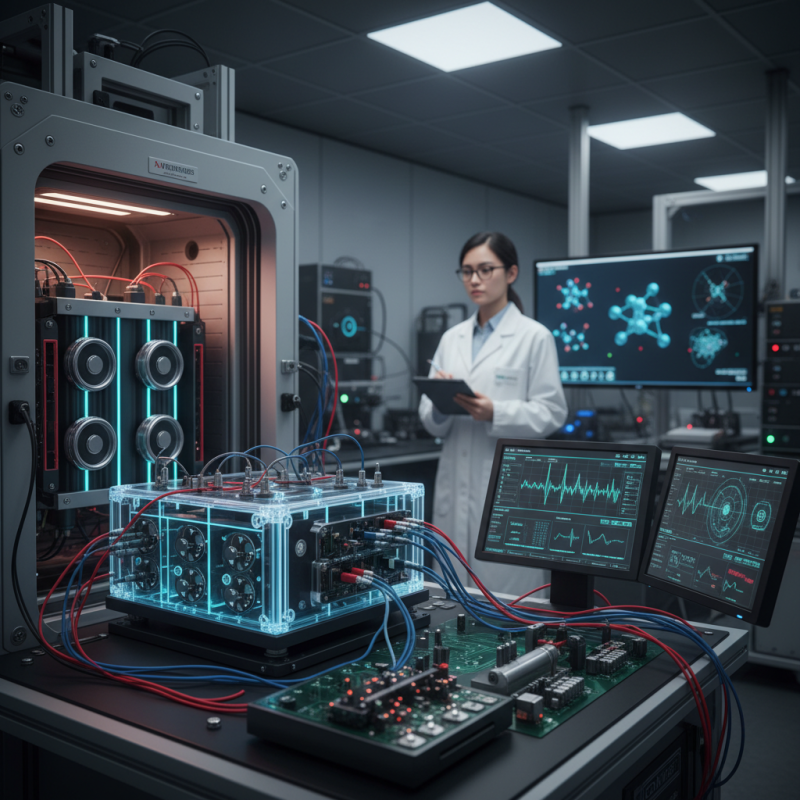

The Battery Test System is essential in today's technology-driven world. Experts like Dr. Emily Zhang, a leading specialist in battery technology, underscore its importance by stating, "Accurate testing is the backbone of battery safety and efficiency." This highlights the critical role that these systems play in ensuring reliability in various applications, from electric vehicles to portable electronics.

Battery Test Systems evaluate performance under various conditions. They simulate real-world scenarios to assess factors like charge cycles and temperature impacts. This detailed analysis helps manufacturers improve their products. However, as technology advances, new challenges arise in testing methodologies. There may be gaps in understanding how the latest materials behave under stress.

Moreover, the complexity of modern batteries means that testing isn't always perfect. Discrepancies can occur in results, leading to potential improvements needed in test protocols. Continuous evolution in battery technology demands that Battery Test Systems adapt swiftly. Reflection on this dynamic landscape is crucial for future innovation and safety improvements.

Definition of a Battery Test System

A battery test system is a specific setup designed to evaluate the performance of various types of batteries. Such a system typically includes equipment to analyze battery capacity, voltage, and life cycle. It simulates real-world conditions that batteries will face during usage. This helps manufacturers ensure their batteries operate effectively under different scenarios.

Battery test systems consist of multiple components. There are usually programmable electronic loads and power sources. These elements allow for precise testing of charge and discharge cycles. Data collected during testing gives insights into battery health and efficiency. There are times when results may not meet expectations, raising questions about design or manufacturing processes.

Not all battery test systems function perfectly. Some may overlook certain stress factors, leading to inaccurate results. This calls for continual improvement and scrutiny of the testing methods. The goal is to develop reliable batteries that meet consumer needs, ensuring safety and performance in practical applications.

What is a Battery Test System and How Does It Work?

| Test Parameter |

Measurement Unit |

Typical Range |

Importance |

| Voltage |

Volts (V) |

0 - 5 |

Determines state of charge |

| Current |

Amperes (A) |

-10 - 10 |

Indicates charging/discharging rate |

| Temperature |

Degrees Celsius (°C) |

-20 - 60 |

Affects performance and safety |

| Capacity |

Ampere-hours (Ah) |

0 - 100 |

Measures energy storage ability |

| Internal Resistance |

Milliohms (mΩ) |

0 - 50 |

Indicates battery health |

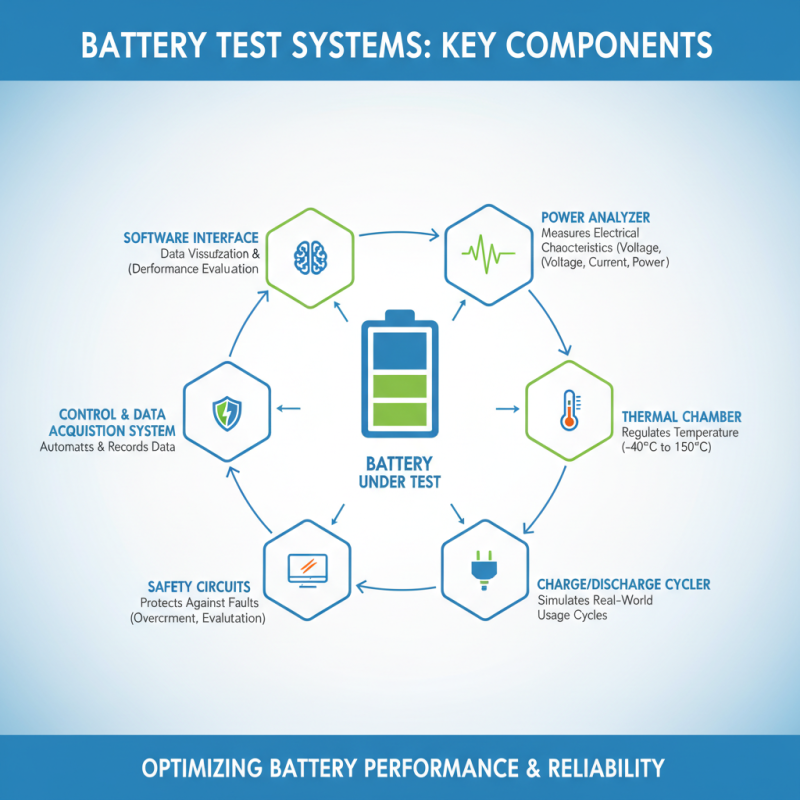

Key Components of Battery Test Systems

Battery test systems play a crucial role in evaluating and enhancing battery performance. These systems consist of several key components, each serving a specific purpose.

One important component is the test chamber. It regulates temperature and humidity. Maintaining optimal conditions is essential for accurate results. Inaccurate conditions can lead to flawed data or misinterpretations. Another critical part is the data acquisition system. It captures voltage, current, and temperature data during tests. According to industry reports, precise data collection is vital for assessing battery lifespan and performance.

Another significant component is the power supply. It provides the necessary energy for various tests, such as charging and discharging cycles. Many testing failures stem from inadequate power supply characteristics. Furthermore, the software used in battery testing systems is essential. It analyzes collected data and generates reports. A common issue is the lack of user-friendly interfaces, leading to mismanagement of results. Overall, having the right components is vital for effective battery testing.

Types of Battery Testing Methods

Battery testing is crucial in evaluating performance. Various methods determine how batteries perform under different conditions. Some popular testing methods include

capacity testing, cycle testing, and thermal performance testing.

Capacity testing measures the total energy a battery can store. This helps in assessing its efficiency.

Cycle testing evaluates a battery's lifespan through repeated charge and discharge cycles. It reveals how

chemical reactions degrade over time. Thermal performance tests the battery's behavior and safety during temperature fluctuations. Each method has its benefits and limitations.

In practice, not all tests can simulate real-world conditions perfectly. Some tests may overlook unique scenarios that could affect battery life. Manufacturers often need to revisit their testing strategies.

Continuous improvements are essential to enhance reliability and safety in battery technology.

Working Mechanism of Battery Test Systems

Battery Test Systems are crucial for evaluating the performance of batteries in various applications. These systems assess capacity, cycle life, and efficiency. They help in understanding how a battery operates under different conditions. According to a report by MarketsandMarkets, the battery testing market is expected to grow significantly, reaching nearly $800 million by 2026.

The working mechanism involves several steps. First, the battery is connected to the testing system. The system then performs charge and discharge cycles. These cycles simulate real-world conditions. Data collected during these cycles are analyzed. This process helps identify weaknesses in battery design. Often, manufacturers overlook certain factors, leading to ineffective battery performance.

Test data can reveal inconsistencies. For example, some batteries may degrade faster than expected. This can raise concerns about safety and reliability. Additionally, discrepancies in testing can lead to misunderstandings regarding battery longevity. Continuous improvements are necessary. Industries must adapt to evolving technologies and standards to enhance battery efficiency.

Battery Capacity Testing Results

Applications of Battery Test Systems in Industry

Battery test systems play a crucial role in various industries. They serve as essential tools for evaluating battery performance. These systems help determine capacity, lifespan, and safety standards. By simulating real-life conditions, they provide valuable insights. Manufacturers can optimize their products based on accurate test results.

In the automotive sector, battery test systems are vital for electric vehicles. These systems assess battery efficiency and reliability. Regular testing ensures that batteries meet safety regulations. In the renewable energy sector, they help in monitoring battery storage systems. These systems ensure that energy is stored and utilized efficiently. Poor performance can lead to significant losses, both financially and environmentally.

There are challenges in using battery test systems. Not all tests perfectly mimic real-world conditions. Some tests might not account for extreme temperatures or usage patterns. Organizations must continually refine their testing protocols. These improvements can lead to better battery technologies and safer products. Understanding these nuances is essential for advancing battery performance.

Home

Products

Power Cell Testing System

Digital Battery Testing System

32/48 channel battery charging and discharging test integrated battery cabinet

32/48 channel battery charging and discharging test integrated battery cabinet

40 channel battery charging and discharging test integrated battery cabinet

40 channel battery charging and discharging test integrated battery cabinet

64 channel battery charging and discharging test integrated battery cabinet

64 channel battery charging and discharging test integrated battery cabinet

80 channel battery charging and discharging test integrated battery cabinet

80 channel battery charging and discharging test integrated battery cabinet

Module Pack Testing System

Developing Portable Battery Testing

About Us

Service

Case&Solution

News

Blog

Contact Us

1000V-1500V High Voltage High Current Battery Testing System

1000V-1500V High Voltage High Current Battery Testing System

High-Precision Battery Testing System for Enhanced Performance Monitoring 30V/60V/100V/120V

High-Precision Battery Testing System for Enhanced Performance Monitoring 30V/60V/100V/120V

High-Precision Battery Charge Discharge Test Systems for EV Manufacturers

High-Precision Battery Charge Discharge Test Systems for EV Manufacturers

Precision Battery Test Racks for Cell Capacity & Internal Resistance Measurement

Precision Battery Test Racks for Cell Capacity & Internal Resistance Measurement

Multi-Channel Battery Testing Equipment for Parallel Performance Analysis

Multi-Channel Battery Testing Equipment for Parallel Performance Analysis